Battery Platform

The Ambri battery platform is a ready-to-install DC containerized system, complete with shelves of cells, thermal management, weatherproof outer enclosure, and a battery management system (BMS) for applications that require high energy capacity, frequent cycling, long life and high efficiency.

Cells are assembled onto trays and connected within a thermal enclosure to form a MWh-scale system, which is then coupled to the grid using standard industrial DC-AC bi-directional inverters. The system is insulated and “self-heating” when cycled daily, requiring no external heating/cooling to keep the batteries at operating temperature. Multiple systems are placed together on site are connected in parallel in a daisy chain fashion, eliminating costly trenching and cable runs, enabling unlimited upward scalability for large-scale projects.

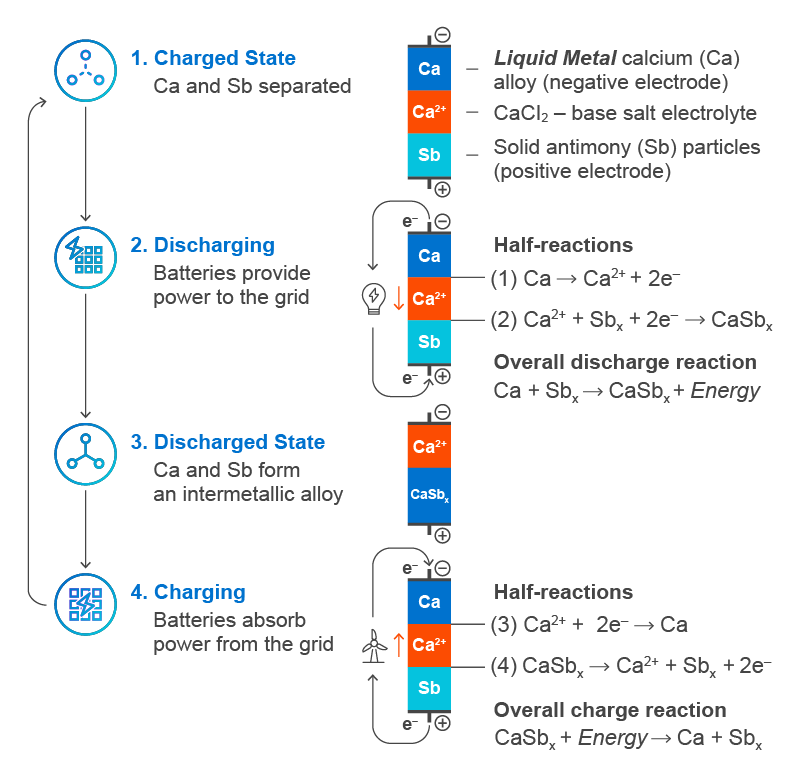

Our Chemistry